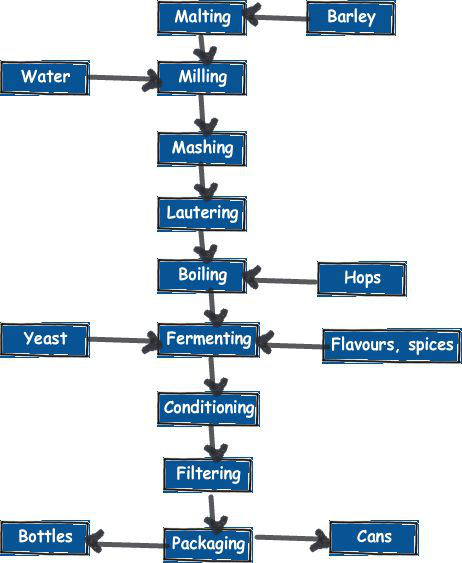

Brewing in the brewery by a brewer makes the beer . However this is not as simple as it is written. The execution is highly precise and in fact sophisticated. It requires a series of steps, to make a good brew. It has to go through the phases of Malting, Milling, Mashing, Lautering, Boiling, Fermenting, Conditioning, Filtering, and Packaging. I have briefly mentioned about each of the steps, followed by a brewing flowchart:

1. Malting: Here the conversion from carbohydrates to dextrin and maltose takes place. The grain used as the raw material is usually barley. Barley as a cereal can be preserved for a long time after harvesting and it is the malted barley that gives Beer its characteristic color and taste.

2. Milling: The malt is then mixed with water to complete the conversion of starches in the grain to sugar. After that the grain is milled to create the proper consistency to the malt.

3. Mashing: This process converts the starches released during the malting stage, into sugars that can be fermented.

4. Lautering: The liquid containing the sugar extracted during mashing is now separated from the grains. It is then generally termed as wort.

5. Boiling and Hopping: Boiling the wort, ensures its sterility, and thus prevents a lot of infections. Hops are added during this stage of boiling.As I mentioned in my earlier post, hops are used to add flavor and aroma to balance the sweetness of the malt.

6. Fermenting: The yeast is now added and the Beer is fermented. The yeast breaks down the sugars extracted from the malt to form alcohol and CO2.

7. Conditioning: Fermented Beer contains suspended particles, lacks sufficient carbonation, lacks taste and aroma, and less stable. Conditioning reduces the levels of these undesirable compounds to produce a more finished product.

8. Filtering: Filtration helps to remove excess of the yeast and any solids, like hops or grain particles, remaining in the Beer. Filtering is the process which produces the clear, bright and stable Beer.

9. Packaging: Packaging is putting the beer into the bottles, cans or some other high volume vessels. One of the most important things in packaging is to exclude oxygen away from the Beer.

These are the basic steps and the style of brewing may vary little. These can be customized to improve the taste of your beer. I will follow up this post with the type of machinery, equipments, weather conditions, for the Beer making process.